May is MBD/MBE/GD&T Month at Origin International Inc., and we’re continuing the conversation about how Model-Based Definition (MBD) and Model-Based Enterprise (MBE) are transforming manufacturing processes. Combined with Geometric Dimensions and Tolerances (GD&T), these methodologies are not just buzzwords—they are the foundation for modern, efficient, and adaptive manufacturing.

Origin News & Events

Topics: origin international, CheckMate, gd&t, MBD, MBE, ScanVis, Quality Control

That’s the reality echoed in a great discussion started by Mohammed Al-arnawoot, with contributions from both traditionalists like Desiree Villeneuve, P.ENG, CSWE and strong MBD advocates like Henk Jörg, who boldly shared that their company hasn’t used drawings in over a decade.

It’s a real-world debate, and the tension is valid.

2D drawings remain the dominant tool for quality checks, quoting, and communication, but they’re also the first thing to fall out of sync when CAD models evolve.

Every time a 3D model changes, the drawing becomes a liability.

😬 Tolerances must be re-updated

🥺 Dimensions re-aligned

🥵 Draftspeople re-engaged

🤢 And QC risks validating outdated data

We've all seen it: drawing revisions that lag behind the model, leading to confusion, rework, and costly delays.

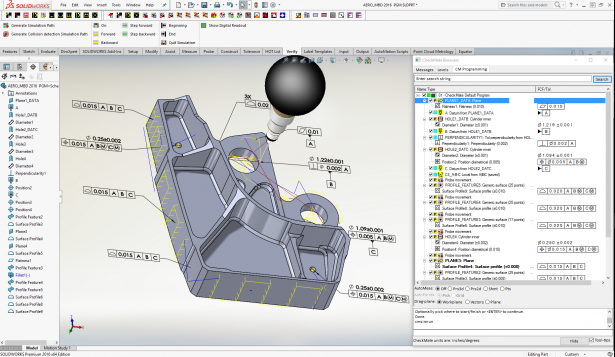

That's why more forward-thinking teams are shifting to Model-Based Definition (MBD), where GD&T is embedded directly in the CAD model.

With this approach:

😊 Changes happen at the source

😀 There's no second disconnected workflow

☺️ Inspection and validation stay aligned with true design intent

At Origin International, we support this evolution with CheckMate for SOLIDWORKS + SoftFit, helping teams:

✅ Validate parts against CAD with GD&T intact

✅ Automatically generate inspection plans and reports

✅ Eliminate redundant drawing steps through model-native workflows

This isn’t just about going “paperless.”

It’s about clarity, accountability, and eliminating waste from design to inspection.

If you’ve ever been burned by a drawing that didn’t match the model, you already know why MBD matters.

I’d love to keep this conversation going:

What’s been your biggest challenge in making the shift to model-first thinking?

hashtag#MBD hashtag#ModelBasedDefinition hashtag#GDandT hashtag#DigitalThread hashtag#CheckMate hashtag#SOLIDWORKS hashtag#SmartManufacturing hashtag#QualityEngineering hashtag#ContinuousImprovement hashtag#MBE hashtag#ModelBasedEnterprise

Topics: SolidWorks, CheckMate, MBE, Model Based Enterprise, CheckMate for SOLIDWORKS, Quality Engineering

1st day of the MBE Summit & QIF Summit was a huge success.

Runs till Friday April 19th, 2024 - Wrap up 11:45am

If you are in the Chicago area, pop by and say hello to the Origin Team.

Origin will be exhibiting at the MBE Summit and QIF Summit April 16-19, 2024 Chicago.

Read MoreOrigin will be participating in the NIST Model-Based Enterprise Summit to be held April 1-5, 2019 at NIST Gaithersburg, MD

Read MoreTopics: origin international, Origin, MBD, MBE, CheckMate for SOLIDWORKS, NIST

NIST Summit Takeaway 3 of 3 -- The Elephant in the MBE/MBD Room: Training

Posted on Tue, May 29, 2018

Our final takeaway is a theme that emerged early in the event: the training gap.

In the Q&A after one of the Day One presentations, an attendee asked “how are we going to be able to implement model-based enterprise when our people need to be re-skilled, new hires are lacking key skills and there aren’t nearly enough qualified people to do the teaching?

In the drawing-based workflows that have predominated for years, designers were not expected to devote much attention to inspection. That ch

anges in the model-based enterprise. Designers are involved with marking up GD&T on CAD.

Topics: origin international, SolidWorks, MBD, MBE, CheckMate for SOLIDWORKS, NIST

NIST Summit Takeaway #2 -- Model Based Enterprise Payback Is Tricky, Systemic Approach Required

Posted on Fri, May 18, 2018

Hadi Jafari of GE Baker Hughes shared his experiences implementing model-based enterprise and the surprises he encountered along the way.

In Jafari’s experience, model-based design (MBD) is a tool that can be confused

with the goal. The goal is to reduce lead time and costs in the design-manufacturing cycle. MBD is simply tools and processes to achieve this goal.

Working out the ROI is tricky when costs and benefits cut across organizational lines. That is, between the OEM and its supply chain partners. When costs and benefits are shared unequally, this adds to the challenge of introducing model-based enterprise.

Read MoreTopics: origin international, Origin, MBD, MBE, NIST

Origin International co-presented 'Automatic Generation of Optimized CMM  Program from MBD on the DMDII Digital Manufacturing Commons and Enabled by QIF' at the NIST Model-Base Enterprise Summit on Tuesday April 4th at 9:20 AM

Program from MBD on the DMDII Digital Manufacturing Commons and Enabled by QIF' at the NIST Model-Base Enterprise Summit on Tuesday April 4th at 9:20 AM

The Digital Thread: Closing the Loop from Design to Manufacturing

Room LACC|409 AB

Session Speakers

Read MoreTopics: origin international, SWW, MBD, MBE, Digital Thread

Embrace the Model Based Enterprise with Origin's CheckMate for SOLIDWORKS

Posted on Thu, May 26, 2016

Topics: MBD, MBE, Model Based Enterprise