CheckMate for SOLIDWORKS®

CheckMate for SOLIDWORKS® is a unique suite of dimensional metrology software for the SOLIDWORKS™ community. Quality professionals and manufacturing engineers use CheckMate for SOLIDWORKS™ to qualify parts, identify and fix problems and improve manufacturing processes.

Check out Origin’s newest CheckMate release. Among the many new features are:

- Evaluate Tolerance Stackups with SoftFit Solver™

- Edit Augmented Features

- Supports for PH20 Flick mode

Check out our what’s new videos. Each is just a minute or two long. You get a great overview of what’s new in action on your screen.

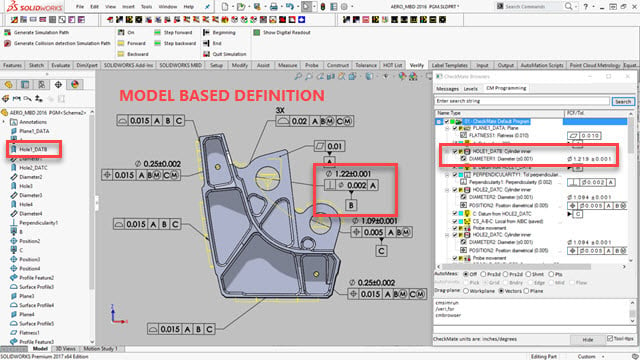

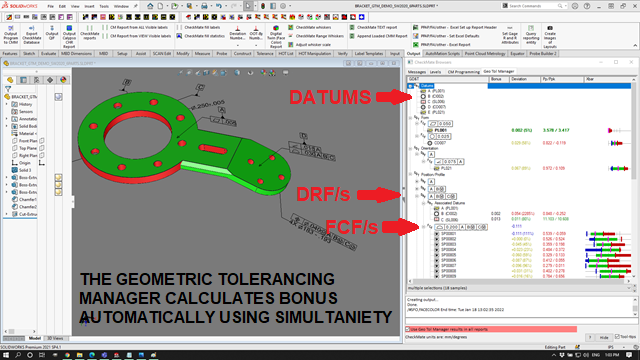

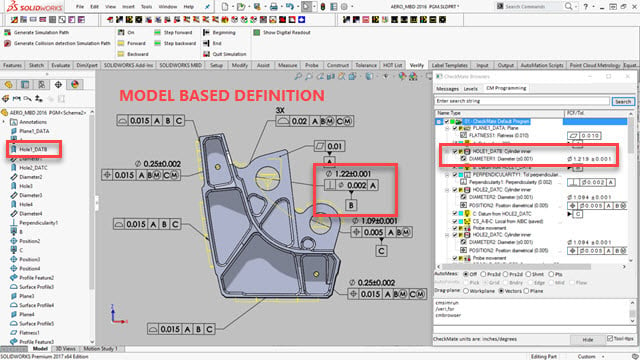

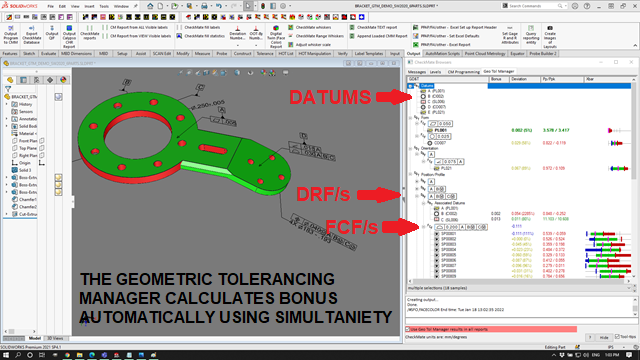

Automate Measurements and Reporting. Many CMMs and scanners are unable to gain the powerful productivity boost possible with SOLIDWORKS DimXpert MBD annotations. You will however, if you have CheckMate for SOLIDWORKS.

CheckMate CMM Programming automatically converts MBD into measurements, and from there to CMM programs for over 60 different makes of CMMs. CheckMate Point Cloud Metrology converts all scanner STL result files into on-screen SOLIDWORKS colormaps and tabular reports in seconds. CheckMate also eliminates the need to manually balloon drawings because it auto-balloons measurements with one push of a button and attaches balloons to each measurement result of each feature.

Unique Ability to Accelerate Pre-Production R&D. CheckMate SoftFit™ Solver provides manufacturing engineers with unique tools to analyze measurement results and simulate corrective action in SOLIDWORKS™. SoftFit™ reduces cycle time in pre-production R&D from weeks to hours. It replaces iterations of tooling and fixtures with simulated corrective actions in software. It eliminates delays for assemblies of child parts by evaluating stackups based on measurements before the part arrive in the assembly facility.

In the high stakes business of weldments and precision-machined castings, SoftFit™ Solver can save hundreds of thousands of dollars in scrap, wait time and unnecessary tool/fixture changes.