- Home

- Products

- Origin APPS

- Integrated Gauging

Integrated Gauging Solutions

Gauging solutions that go beyond Go no Go.

2) Flexible Gauges-Origin's shop-floor flexible solution, is an Origin customised Renishaw Equator™ Flexible Gauge to include Origin's Equator™ authoring software.

The authoring software module allows the end-user to create part programs on their existing Co-ordinate Measuring Machine, measure the "master part". Origin's authoring software module creates from the part program and the measured results file two files used on the Renishaw Equator™ with a click of a button.

These files are a part program converted from the end-users inspection software package to the format needed by the Equator™, and a calibration file generated from the measured results. The Origin authoring software will allow almost immediate use of the Renishaw Equator™ after measurement of the golden part.

Origin APP: Equator™ Authoring

(available in CheckMate or as a standalone windows based App)

Supported Packages: Calypso, PC-DMIS, Sheffield, GeoPack 2100

RENISHAW® and the probe emblem used in the Renishaw logo are registered trademarks of Renishaw plc in the UK and other countries. Apply innovation and Equator are trademarks of Renishaw plc.

Calypso® - registered to Carl Zeiss

Origin App: CheckMateRT (Run Time)

(Available in CheckMate or as a standalone windows based App)

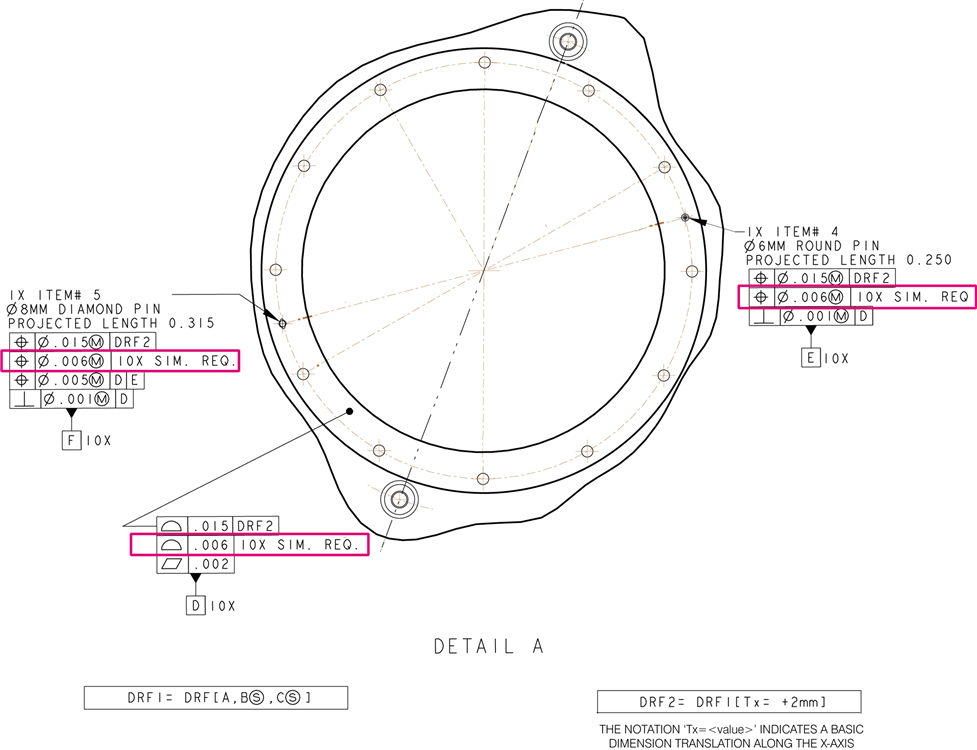

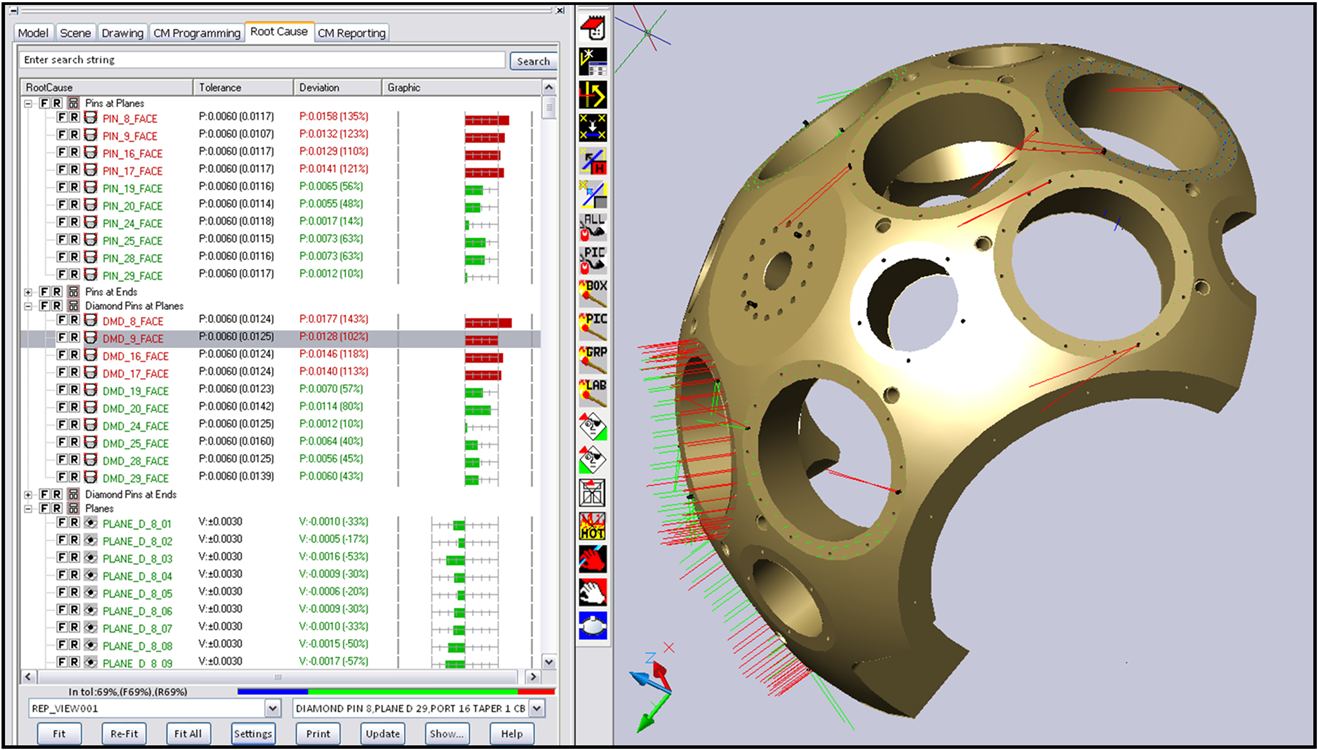

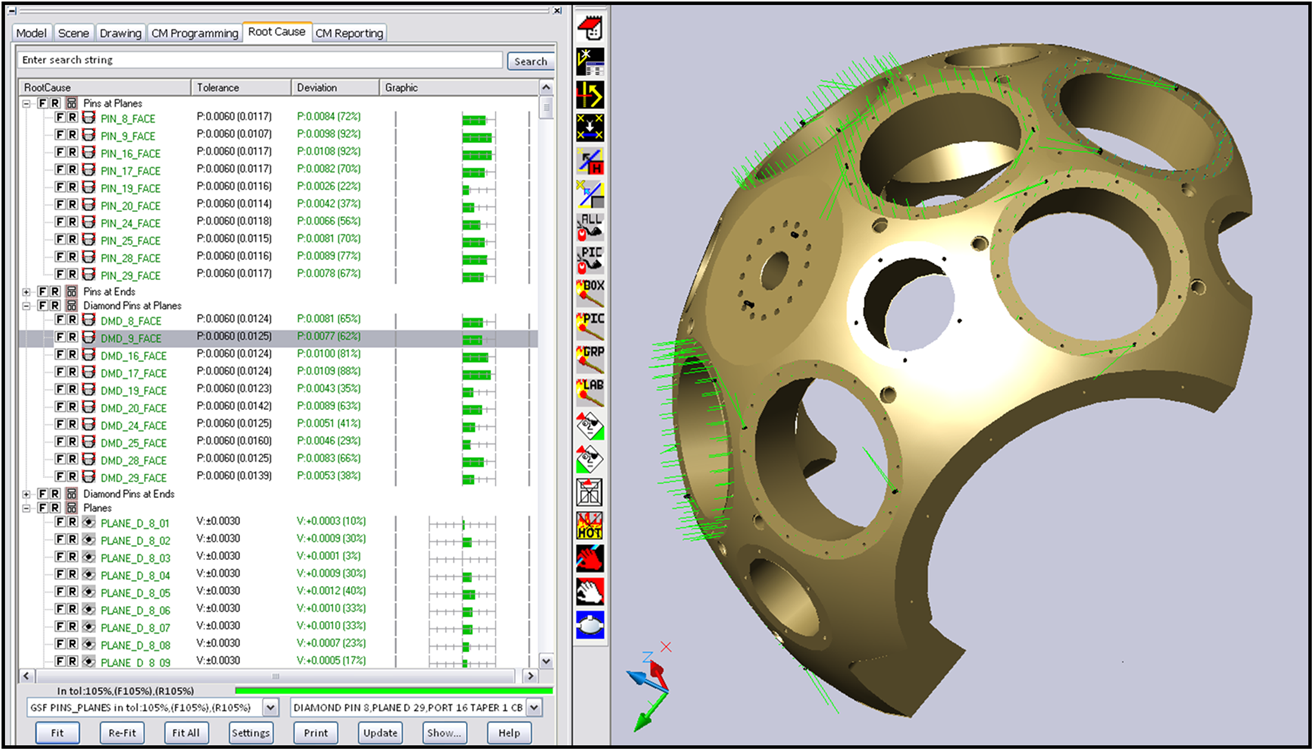

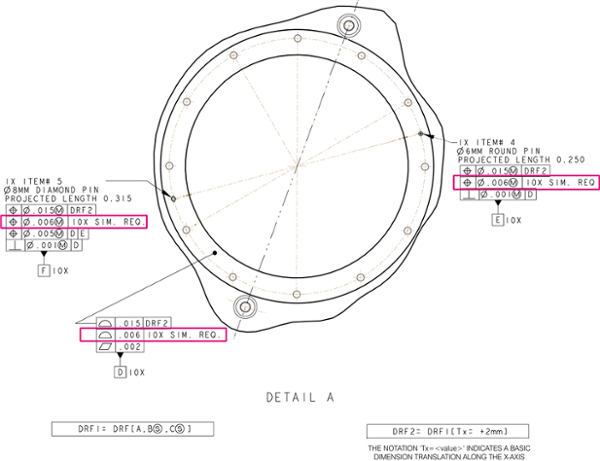

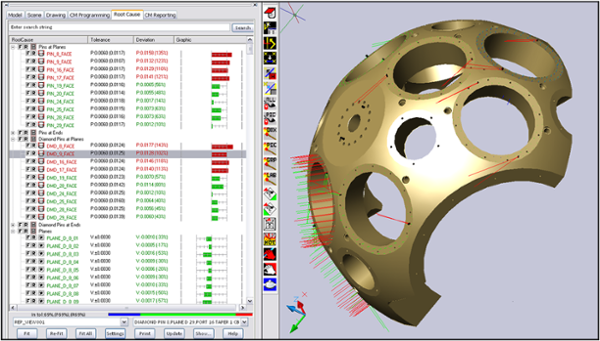

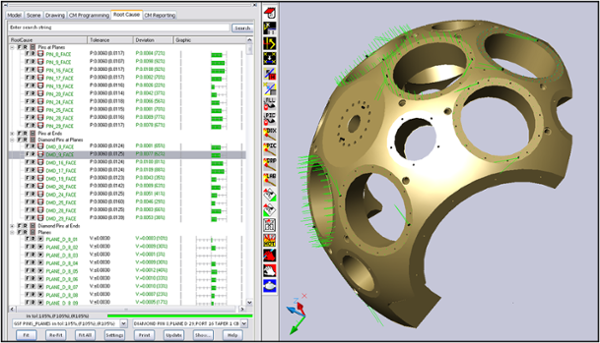

The CheckMateRT (Run Time) Solution takes Q.C. Reporting and Engineering Analysis and wraps them into a seamless system that flows hand in hand with Renishaw’s Equator TM Comparitor. From CMM results, CheckMateRT uses Gauge Simulation Fit technology, correctly evaluating the GD&T and simultaneous MMC conditions across multiple DRF’s, as the print specifies. No longer are the days where the CMM rejects a part while the shop floor go/no-go Gauge accepts it. Then, CheckMateRT takes the data and generates reports for excel, text and stats systems, all seamlessly at program measurement runtime.